As a DPaschoal Group member company, the work developed by Daterra Coffees has helped promote Brazilian special coffees abroad and break prejudices

In the Cerrado Mineiro area, in the region of Patrocínio, at an altitude varying between 1000 and 1200 meters, two neighboring rural properties, the Boa Vista and Taboões farms, are together helping to change the face of the Brazilian coffee growing sector, with lots of experimentation and research. A proof of this is that, last year, Swiss barista Emi Fukahori won the World Brewers championship with a coffee prepared with the Laurina variety, the Frevo microlot, processed through semi-carbonic maceration and produced at Daterra Coffees (www.daterracoffee.com.br). The uniqueness of her achievement was due to the fact that in international championships Brazilian products have always been passed over by coffees from Panama, Colombia, Yemen, etc.

Photo by Daterra Coffee

Everything is impressive here, starting with size. The Boa Vista and Taboões farms cover together an area of 6,618 thousand hectares, equivalent to 6,618 soccer fields. Their farmyard is 30 thousand square meters long, and post-production also counts on 44 dryers. They also use 40 harvesting machines, all of them made in the farm itself, by their own collaborators. To ensure smooth operations, 700 professionals from many different areas and specializations are employed, all of them under the Brazilian CLT (Consolidation of Labor Laws) regime.

Daterra seedling nursery: from this property, 15 million coffee trees have been planted

Part of them from experimentation

Their coffee production area amounts to 2,718 hectares, with 15 million coffee trees, which characterizes a large property. But differently from other farms, more than 50% is dedicated to preserved areas. And it is here that Daterra Coffees outstands among many other properties. Productivity and an earnest commitment to sustainability are the guiding principles of their business!

In the Cerrado Mineiro region, the law requires that 20% of farmlands in a property are preserved. “We preserve 50%. We have to give back to the ecosystem what we have consumed,” said Gabriel Agrelli.

By influence of illycafè’s founder, Ernesto illy, who believed the Cerrado Mineiro region was the best place to produce quality coffees in Brazil, DPaschoal’s CEO, Luís Norberto Paschoal, who had already had other farming experiences in many places around country with different crops, asked his General Manager, Agronomic Engineer Leopoldo Santanna, to look for the best lands in the Cerrado region to start producing quality coffees.

Photo by Daterra Coffees

Photo by Daterra Coffees

by Daterra Coffees

The Boa Vista farm was the first to be acquired, 26 years ago. As for the Taboões farm, it was incorporated in the following year. However, both were in poor conditions and it was necessary to reconstitute the Cerrado ecosystem, its flora, fauna, soil and springs. And to do that, they established a partnership with ESALQ, the Luiz de Queirós University, and devised Daterra’s Coffees first environmental propositions. “It took more than 10 years to recover the area just enough to start good quality coffee production,” Gabriel told us. It was the first farm in Brazil to obtain the Rainforest Alliance certification in 2003, and then the IS0 14001 certificate. In 2018, it achieved recognition as an A-level facility by that very certifying entity.

The Cerrado region has demonstrated to be ideal for producing quality coffees at large scale, and also for enabling mechanized production, since, despite local altitudes, lands are flat. “It enables us to produce at scale, high-quality coffees though, even utilizing tractors, harvesters, and etc.” explained Gabriel.

About 60% of Daterra is irrigated

The weather is perfect for coffee: “Coffee is a demanding crop, it requires thermal amplitude, and well-defined seasons, with rains during the Summer and a dry Winter, the harvesting time. And we have all that here, despite climate changes, which have been studied by us since the farms were acquired,” he told us. An example of that is the farm’s rain map, as surveyed from 1988 up to today.

In the last few years, both the lowest and highest temperatures have gone up due to global warming. So, we need to study it because high temperatures also change the way a tree produces its fruits. Stress is different, and their metabolism too. Here we study which varieties will manage to resist higher temperatures, and how will pests propagate themselves? It is really a day-to-day effort. We analyze all the data we collect, we have access to the farm’s rainfall history.

“We try to find the best formula in order to become great farmers and, at the same time, deliver quality. In addition to being sustainable, we had to achieve high quality blends. So, the formula we found was to create many systems to stagger production,” said Gabriel.

Irrigation pivots

Producing quality at large scale

The production area is divided into mini farms and each one of them has between 5 and 15 hectares, the equivalent to a small property in the southern region of the State of Minas Gerais. Altogether, there are 516 different areas to work on.

From each one of those mini farms data is collected every day on variables such as soil composition, what has the quantity of rainfall been in a specific plot, which planted variety it has, date on which the fruit has ripen, and etc. “We employ 43 people who circulate around the farm all day long, on motorcycles, collecting all kinds of information, including from the available pluviometers. Since we do not have access to the Internet on field, our collaborators have go ride on a bike to the assigned pluviometer, where they collect information through a QR Code in their cell phones and, when they arrive at the property’s office, they activate the wi-fi feature and are able to share that information with the staff from our technology area. After that, we are also able to perform coffee maturation analyses and then just harvest those crops that are really ripe,” he clarified.

Clock collecting information and passing it on to the technology industry

Diversity and variety

Another way of maintaining quality in coffee crops is by planting many different varieties. At Daterra Coffees they amount to 14: yellow Catuaí, red Catuaí, yellow and red Borboun, Aramosa, Arara, Naomi, Tupi, IAC 125 RM, Acaiá, Ouro Amarelo, Paraíso, Catucaí, and Mundo Novo. These varieties will comprise our coffee menu, divided into three large brands, Classics, Collection and Masterpiece, this latter dedicated to microlots of highly special coffees.

“Our most desirable asset is the consistency of our coffee blends, one of the lessons we have taken from illy. Inspired by the global wine industry, we blend the coffee varieties and so are able to replicate the same quality year after year,” he enthusiastically claimed.

Photo by Daterra Coffees

In addition to consistency, the variety of species also enables harvesting at different times. “Each variety ripens at a different time, which could be a problem. But for us that’s excellent. Although we have more than 40 harvesting machines, it would be impossible to harvest everything at once,” he said.

Around 90% of their harvesting procedures is selectively mechanized, as Gabriel is proud to stress. “Our staff only goes to field to harvest crops at the right time,” he explained.

The only areas managed by Daterra Coffees where harvesting is done manually are those where coffee plantations are very young, and in the microlot, with more delicate species such as Laurina, Gesha and Aramosa.

Daterra partners with the most important universities and research agencies in the country

And, by investing in the future, the Boa Vista farm is home to a vast 10-hectare research field, in partnership with IAC, and with more than 120 different planted varieties, which are not commercially available. Today, they are used for research, especially in regard to the effects of global warming. “Together with IAC we research new inbreeds to try and find species more resistant to global warming, and which can properly resist water scarcity, for example,” said Gabriel.

Coffee is a shrub that came from the forests of Ethiopia, in Africa, the cradle of coffee. There, it buds and grows very slowly by the shade, below large trees. When this crop was spread around the world, it was also taken to shaded cultivation areas. In Brazil, its history has been different. We have always applied a lot of research and technology to agriculture, and IAC itself has a 135-year history. Brazilians have developed coffee growing under full Sun, while looking for varieties that could withstand high temperatures. Today, many varieties are not even able to provide large yields under the shade. Pacamara and Laurina, for example, are being tested in the farm both under full Sun and in shaded areas, so we can analyze them. The problem is that in the Cerrado region trees are not that high. The majority of them are whither and dry. To build a shaded lot we have to plant exotic species, such as Mahogany, which also came from Africa, and which is not recommendable in ecological terms.

Laurin Field

Laurin is being grown in full sun and shade

Sunset at Daterra is a surprise for visitors

The labs

Daterra’s Coffees technicians count on three different labs: two of them are close to the production area, while the third one is located just beside the management building. Actually, it serves as a true cafeteria, together with a tasting room.

There are three testing labs

After coffee has been produced and processed, it needs to be tested under many different methods. Our client, after having purchased it, wants to know through which method its qualities will better emerge.

“Usually, farms only have a cupping structure, but that is not how people consume coffee in a cafeteria. If our client has a specific objective, here he can taste the coffee he has opted to purchase using many different methods, such as drip coffee, and an espresso machine, which by the way is a La Marzocco machine utilized only for that purpose. Our farms also have, in an annexed area, a roasting room, equipped with a 1.1-kg Probat and two 100 and 120-gram sample roasters.

Proof Lab

The farm employs six professionals, trained by the SCA methodology, and fully dedicated to tasting coffees. During harvesting, which goes from May to August, we have estimated that each one of them taste around 30 thousand cups, and that only to determine the exact harvesting time of the grains.

Masterpiece: The microlots

The Masterpieces collection is composed of way too special microlots

At Daterra Coffees, just 1% of all their coffee blends is produced in microlots. Masterpiece blends are sold in an auction, promoted by the farm every year, in November. In 2018, the Frevo blend, for example, became the most expensive Brazilian coffee in history. With little more than 72 kg available, that lot was sold for US$ 141.10 per libra (450 g) to importers from Spain and Canada.

Made from the Laurina variety and processed with the Semi-Carbonic Maceration fermentation technique, that coffee achieved great highlight after being utilized in the presentation made by barista Emi Fukahori, the Swiss contender who won the World Brewers Cup international competition, held last year during the International Coffee Week, in Belo Horizonte, Minas Gerais.

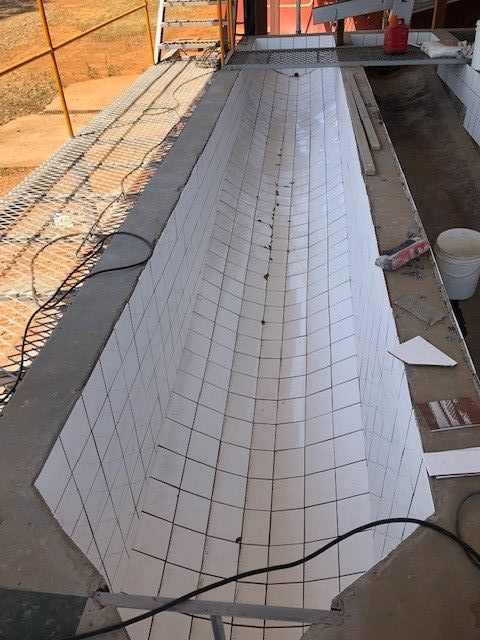

The microlots are produced totally separate in the experimental farm, which has suspended terraces, dryers and fermentation tanks. Here, coffees are selected to be part of the Masterpiece collection menu

Daterra Coffees has adopted the practice of baptizing its lots, the Masterpiece blends, under names that refer to Brazilian culture. In 2017, microlots were baptized after characters from Brazilian mythology. In 2018, after musical styles such as Carimbó, Funk Carioca, Ijexá, Toada, Chorinho, Marchinha, and etc. Each one of them was also given a soundtrack exclusively developed for the campaign. Soon, the new campaign for the 2019 auction will be launched.

The Masterpiece brand includes blends with a score above 88 points, produced in the Experimental farm, which is inside the very property, but which is fully equipped to operate separately from Daterra’s remaining coffee production facilities. They use their own machines, suspended farmyards and fermentation tanks, similar to Colombian ones, built more than seven years ago, when they started researching fermented coffee blends.

Suspended Barns or African Beds on Experimental Farm

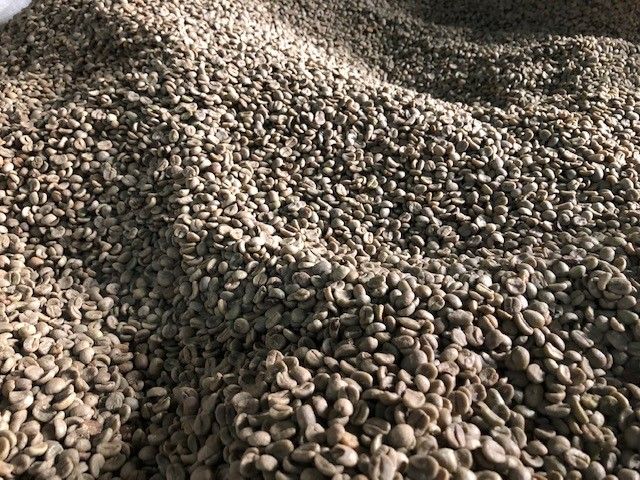

Microlots are produced using experimental coffees and unique varieties such as Gesha, Laurina, Catuaí, Mundo Novo, among others. Around 150 bags are produced every year. They are vacuum-packed, in a packaging designed and patented by Daterra Coffees, called Pentabox.

They are submitted to differentiated processes, or come from differentiated varieties, or when in a specific year nature has been kind and produced a spectacular coffee harvest. In sensorial terms, the sky is the limit: “these are super floral and super fruited coffees, with the taste of wine, exotic, with phosphoric acidity, and foreigners usually claim they don’t even taste like Brazilian coffees. I think they want to flatter us by saying that, right?,” said Gabriel rather mockingly.

The fermentation methods

On the experimental farm, fermentation tanks inspired by Colombian farms have been built

At the start of its experiments with different fermentation methods, around seven years ago, Daterra Coffees summoned a team of researchers from the University of Lavras, headed by a teacher specialized in cocoa, manioc and coffee fermentation, and they started to perform many types of tests: cocoa and cachaça yeasts, under natural fermentation methods using either a lot of water or little water. But the results were disappointing. “Those blends did not achieve a 90-point score and lacked the body of Brazilian coffee, one of its best characteristics,” he told us.

Silos

Specialty coffees ready to be packed

In the fourth year, they invited people from French coffee roaster Lomi to take part in the “Our plot of Daterra Coffee” research project. And Lomi suggested they also employed the carbonic maceration process, which was being utilized to make Beaujolais wines, in the region of Burgundy. Those were low-quality wines and entirely for commercial purposes, and through carbonic maceration have taken a quality leap among consumers.

Lomi’s staff came to Brazil and helped develop the entire process. That experiment has been highly successful, and a proof of this is that the Brazilian coffee blends produced by Daterra Coffees are today desired by baristas from all over the world.

Coffees above 84.5 points are packaged in Daterra’s patented by Pentabox

Below you’ll find a small chat with Mychel Henrique, responsible for Daterra’s IT area.

Mychel Henrique, IT Manager at Daterra

Grão Especial – For how long have you been working at Daterra?

Mychel Henrique – I’ve been working at Daterra since 1996, in the Information Technology and Organizational Management areas. My basic education comes from the Information Technology area, and I had the chance of complementing my studies, including an Environmental Management graduation course, and specializations in areas such as Business Analysis, Computing in Agriculture (with emphasis on Administration and Costs) and upgrading courses in the Management, Projects and Accounting areas.Grão Especial – During my visit to the farm, I saw that they use QR Codes to collect information on field, especially in regard to the quantity of rain. I’d like to know how that process works for the better. I know that when your employees arrive at the office they are able to share data. What kind of software do they use to analyze the collected data?

Mychel Henrique – We use a web/mobile platform for development purposes, which enables us to utilize all the features in a smartphone (GPS, camera, QR Code reader, etc.) to collect data. That information is processed in the web platform and the results are presented through “Templates,” easy to access and to interact with for end users, such as Excel spreadsheets or Google Earth maps.

That specific case was an excellent example of benchmarking, since we found that solution when it was being used by a large company from the dairy sector, specifically in their logistic process to collect milk at farms. Originally, we were looking for a tool that could be applied just to perform phytosanitary monitoring but, since our very first contact with it, it was possible to dream and envisage a large number of scenarios. Today we may say that, in terms of data collection and monitoring, that tool is utilized from A to Z, from phytosanitary to rain and temperature monitoring, including pressure gauges, irrigation systems, traceability and coffee product quality evaluation, registration and control of all beverage tastings before harvesting, dryers and granaries, up to the management of agronomic prescriptions and management of the executed operational services.Grão Especial – What is the current importance of technology for Daterra’s activities?

Mychel Henrique – When the majority of agribusiness companies were starting some informatization process still very shily and full of doubts, Daterra was already betting, with great conviction, that Information Technology would be a differential for the business and was investing in education and qualification.

Since the company’s conception, the IT area has been treated as a great management differential, and consequently for the company’s evolution.

In 1997, when mobile devices were starting to evolve, Daterra was a pioneer in the Cerrado region, by importing and implementing data collectors from the United Kingdom to schedule tasks on field, providing a great improvement to us in terms of quality and agility of the information gathering actions to support our decision-making process.

Around the year 2000, all farms/stands were already georeferenced and we were able to kickstart the first actions in the process to sectorize our stands, where we divided an area with approximately 2,700 hectares into more than 230 mini farms, with individualized agronomic management and cost control, striving to implement an agriculture of “information” and with greater “precision.”

Currently, and it could not be any different, the company continues to bet on quality information to foresee scenarios and make quick decisions based on facts and figures.Grão Especial – Where is the highest demand for it?

Mychel Henrique – The highest demand is found, without any doubt, in the main business of the company, and anything that is directly or indirectly linked to coffee is a priority for us. But, obviously, to make sure everything works properly we need to maintain an excellent performance at the back-office structures, which also implies a great demand for resources.Grão Especial – I’ve seen that harvesting machines are made in the farm. And with IT, how does it work? Are the solutions also developed inhouse ?

Mychel Henrique – A part of our solutions are still fully developed inhouse, they are usually more associated to specific areas of our business, but we also use market solutions, such as SAP B1 and platforms that we may classify as “mixed.” These are very dynamic technological solutions regarding their applications and use, and offer us the possibility of customized development, with great flexibility in relation to the data structuring, collection and modeling processes.

The primordial issue is not to use the most famous software in the world available in the market, or to have the best solutions developed internally, but to have solutions that make sense and generate results for the business. Oftentimes, people spend time and thousands of dollars with highly sophisticated IT solutions, and they end up not adequately using even a third of the generated information.

Daterra strives to always be at the forefront and to be a pioneer in the use of technology, but it thoroughly and carefully evaluates any and every innovation, separating what is a mere fad from what may really provide benefits and aggregate value to our business. If in any situation a simple Excel spreadsheet can solve a problem, that spreadsheet will be certainly used.Grão Especial – Are you already using artificial intelligence? How do you see the use of AI on field

Mychel Henrique – I see there are many promising segments in Artificial Intelligence, and they have been advancing with excellent results in the agribusiness sector. I believe they will increasingly and more quickly evolve, and some things will make a lot of sense, while others not much. We have already implemented some initiatives where AI will be present and will make a significant contribution in terms of results, such as in water resources/irrigation systems management, soil management, pest and disease management, and optimization of agricultural operations.