The sustainable factory was installed in the middle of the Amazon Forest

Danke (www.dankecacau.com.br), which means “thank you” in German, is a new chocolate brand that is emerging with more than 130 years of history. Ernesto Neugebauer, its founder, came from a family of chocolate masters. His grandfather, already worked with chocolates in Dresden, Germany and, when immigrating to Porto Alegre, built the first chocolate factory in Brazil, Neugebauer in 1903, equipped with steam engines, coming from Europe. The whole family worked in the manufacture of chocolates, including Ernesto, who, at the age of 18, even before entering college, had already fallen in love with this sweet universe.

Much later, in 1982, Ernesto founded with his father and brothers the Harald brand (whose segment is bars, bases and covers for pastry shops and restaurants) that he presided for 38 years. Until, in June 2020, in the middle of the coronavirus pandemic, he started his newest adventure in the world of chocolates, inaugurating Danke.

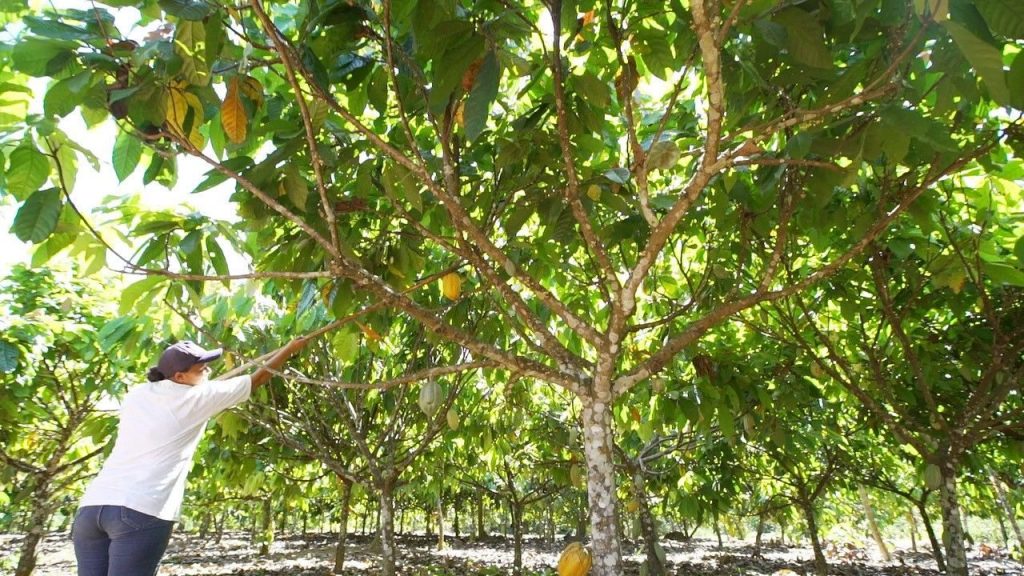

The company arose with a strong concern for the sustainability of the entire chain and, for this reason, they built their plant in Altamira, Pará, in the full exuberance of the Amazon Forest, close to the more than 100 small family farmers who supply cocoa for Danke, allowing 100% traceability. The factory’s boilers are powered by biomass, which reduces the emission of carbon into the atmosphere.

CEO Ernesto Neugebauer, who is above all passionate about chocolate, has granted an exclusive interview to Grão Especial. Check it out below:

Grão Especial – You have cocoa farms in Bahia and Pará. Why did you decide to build the factory in the middle of the Amazon forest?

Ernesto Neugebauer – With no intention to belittle Bahia’s cocoa production, in my opinion, the future of cocoa is taking place there in Pará. I think not only in Brazil but worldwide (productions closer to the Equator line). We have many areas in which we can grow, southern Pará is huge and they have a lot of land that became pasture; they destroyed the Forest. Cocoa can help restore these locations. Cocoa is a very special crop, as its tree is a kind of understory, with large and big leaves; it is a plant designed to grow in the shade. It does not tolerate wind either and, if it is inside a forest, it is also protected from water stress. In other words, in the forest, the cacao tree finds a suitable biome, since it requires an environment of fertile soil.

We see this in Pará. Well-managed cocoa is much more profitable than livestock or soy. It is not the salvation of the world, there is not enough cocoa in the world to recover everything that has already been deforested, but…

Brazil is able to be the largest cocoa producer in the world. Today, we are the fifth or sixth only!

Grão Especial – When exactly did Danke start to emerge?

Ernesto Neugebauer – It was from 2000, before I was very focused on consolidating Harald. And then I started to see the invasion of Belgian chocolates in Brazil and that gave me a pain in my heart. Brazil is the country that brings together all the best to produce excellent chocolates: we have cocoa, we are the third largest producer of powdered milk, we are a major producer of sugar, so we have a rare condition. This is the land of chocolate! We have all the raw materials to spare, all in one place. It doesn’t exist anywhere else in the world!

So, I was very impacted by this situation and decided that I was going to make chocolate. A few years before that, in 1988, I went to Bahia to visit some cocoa farms that were already doing a great job in terms of quality. I visited the farm named Leolinda do João Tavares, Vale Potumuju, Juliana Aquino, from Baiani (see the story here), Nick, and saw that these producers were producing excellent quality cocoa. When I tasted their cocoa I was ecstatic: it was the chocolate of my childhood. The taste of my childhood came up immediately.

There is no secret here: to make a good chocolate, you must have a low bitterness cocoa and a smooth cocoa, with a very balanced acidity. And our mission at Danke is to make the best chocolate in the world, but not for half a dozen people. We want to do this in order to have democratic consumption, at an affordable price.

Grão Especial – Is scale not a problem for Danke?

Ernesto Neugebauer – Scale is not a problem, but a challenge. But being a niche brand is not good for consumers. We are in no hurry to grow, but we don’t want to waste any longer either. Our concern is quality. At the beginning of last year, we did a survey with the small cocoa producers that are close to our factory in Pará and the vast majority answered that they worked with quality cocoa. But when the almonds arrived at the factory, we noticed that they did not meet our requirements. In this sense, the pandemic helped us to create a base of cocoa producers of excellent quality.

Grão Especial – How would you describe Danke’s chocolate?

Ernesto Neugebauer – Our chocolate is not yet complex. We were very concerned with hitting the cocoa roasting point; this was our first mission. For those people with a more refined palate, they will find our chocolate smooth. But my dream is to work with new fermentation techniques, making a blend of varieties that pleases the average Brazilian palate, but that allows us to bring a greater complexity of flavor to chocolate. Nowadays, cocoa is fermented and this subject along could give you a week of interview! What we do today in the fermentation of cocoa in Brazil is what we do in the fermentation of a wine from the bottle. Many families have been producing wine for three, four centuries. Cocoa has been fermented for less than 80 years, roughly with no control in Brazil. We still don’t bother to divide the cocoa species as we do with grapes. And each type of cocoa has a different fermentation, like grapes. In that sense, I think that the culture of cocoa is much more similar to that of wine than coffee. Coffee also ferments! But cocoa fermentation is essential, as it is at this stage that the precursors of aromas are formed in chocolates! When they do not have these biochemical elements within this well-formed seed, they will not exist in the roasting of the almonds. Cocoa has to be fermented in a very appropriate, controlled manner, with alcoholic, aseptic fermentation. Drying has to be appropriate, as it continues to exist within the grain, as well as maturation.

The almonds have to dry in the sun for 7 to 15 days, this process is essential, as the animals (from fermentation) work in comfort. In drying and maturation, chemical reactions continue to take place. On the first day, cocoa has to drop its acidity, but it cannot be too slow or too fast. If it goes too slowly, it will mold. And if it goes too fast, it becomes acidic. It has to be turned over three, four, five days, absorbing the humidity of the night, the heat of the sun! Anyway, this is very little-known knowledge within the cocoa chain. There are many chocolate makers who do not know these processes. They don’t know exactly what Maillard’s reaction is, which occurs in the roaster.

The folks at the Bean to Bar chocolate are bringing this knowledge. But it is still difficult for the big producers to use it. It is a turning point for our market. I really like what the people at Chocolat du Jour are doing, from Mendoá, as they are pushing innovations. The big ones are following them, as happened with craft beers. It is necessary to change the chain, since consumers are asking for that. We need to bring knowledge to the entire cocoa chain and scale it up!

Grão Especial – After a year, how many employees does Danke have?

Ernesto Neugebauer – There were 100 of us, but we are over 110 at that moment.

Grão Especial – And did everything that you foresaw in that first year of production happen?

Ernesto Neugebauer – No way. It went all wrong. The year of 2020 was a very difficult one for us. We had to refine the strategy, ensure the supply of quality cocoa, we had no experience in retail, we were unknown in supermarkets, we were unable to establish contact with the major chains, until we managed to sell the Danke brand in Santa Luzia, in San Marché, which are very strong brands. And then, the doors opened at Pão de Açúcar, Carrefour, Big, Festval, Záfari. We are very happy.

Grão Especial – What about the foreign market?

Ernesto Neugebauer – Look, we are already receiving some proposals but I do not imagine our brand being exported in the next five years. As long as you have imported chocolates being sold at gas stations, we have a lot to do in the domestic market.

Grão Especial – Was price a problem?

Ernesto Neugebauer – Price was never a problem. The most difficult thing, as I said before, was the fact we were strangers. We also made an option not to use plastic, the market does not appreciate it. We only use plastic of vegetable origin, and it costs more. On our first Easter, this year, we did not use plastics in our packaging and we are working to eliminate it throughout our factory.

Grão Especial – Will you use ingredients from the Brazilian biome in your products?

Ernesto Neugebauer – Yes, sure! I have a big dream of using the sapucaya nut, which is native one and has almost been decimated. I’m planting on our farm in Bahia, but it takes a little while for it to grow. The quality of your chestnut is fantastic, it has little oily load, it is lighter, it will undoubtedly be our first new product. When I worked at Neugebauer, former president Getúlio Vargas loved this chocolate. His daughter, Darci Vargas, used to call us to order a box of chocolates with sapucaia nuts. And we used to go to the Catete Palace, headquarters of the Federal Government at the time, to deliver the box of chocolates! And today, unfortunately, no one else knows it.

The next chocolate will be made with cashew nuts from Pará, then Baru, later on the Pequi seed, much tastier than hazelnut and almond. The variety of Brazilian nuts is huge.

Grão Especial – How to change the perception of the foreign market regarding the quality of Brazilian cocoa?

Ernesto Negebauer – You have addressed an excellent topic. Building credibility takes more time. We have already had a large production of quality cocoa in Brazil. It has worsened a lot in the last 40 years and, now, we see a revival of concern about quality. We see big producers like João Tavares, the Panorama farm in Pará, Seu Nenê, also in Pará, so let’s make up for the wasted time.

Grão Especial – And what do you expect from what remains of 2021?

Ernesto Neugebauer – Look, we’ve done well so far. But the question is: “what can be inserted in this new world? What is our mission? We are very clear that we cannot expect anything more from the Government. We, from the private initiative, must create wealth. We have to take better care of things. I am totally against imported chocolate in Brazil. We have to work to make cocoa, Brazilian chocolate, relevant to the Brazilian economy. There are 60 thousand cocoa producers and 97% of them are from small family farmers. We have to privilege Brazilian chocolate, the cocoa producers, paying fair prices and treating them with the proper value! The secret of good chocolate lies in them, in the producers, not in us.

Large companies are trying to change these perverse dynamics of paying producers badly. But they sin by their gigantism and their sustainability speeches are only in communication. They don’t even have a sustainability report, just a balance sheet. They keep reviewing and postponing, from 2025 to 2030, (see the story on child labor in the cocoa fields here) they cannot get rid of the system. They pay the producers badly, use child labor in the cocoa crop. There are two million children working in the cocoa fields worldwide! Two million! It will only get better when it hurts in the shareholder’s pocket. I know a lot of cool, well-intentioned executives from these multinationals. But they keep painting walls in schools and saying they are sustainable. And this is bad for everyone. The worker, the producer and the entire chain loses. And the consumers have to demand changes too!

Memories Line

Photos: photographer Nani Rodrigues