Making their own Bean to bar chocolate is the new challenge for the Gutzeit family.

The Gutzeit family, owner of the Panorama farm, is originally from Germany and migrated to Brazil at the beginning of the last century. They settled in Espírito Santo, as missionaries and, in the mid-60s, decided to move to Pará, to the municipality of Medicilândia, in the middle of the Amazon rainforest, and founded an agricultural school.

Entrance to the Panorama Farm

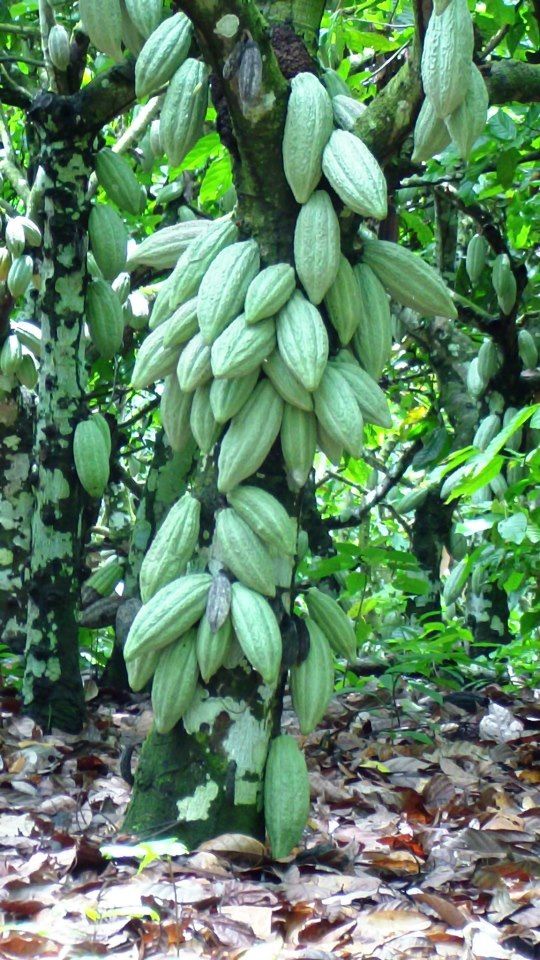

Ervino and Erna Gutzeit formed, next to the school, a farm named Panorama, whose objective was to practice sustainable agriculture. They chose to plant cocoa, as it is native to the Amazon and can be grown in the shade of the forest.

Cocoa taking advantage of the shade of the Amazon rainforest

Today, the property is run by the family’s second and third generation, daughters Eunice and Elcy, as well as grandson Elton.

Eunice and Elcy Gutzeit, in the special cocoa plantation of the Panorama farm

Currently, despite all logistical difficulties, the municipality of Medicilândia has become the largest cocoa producer in the country along with five other nearby cities: Pacajá, Anapu, Vitória do Xingu, Brasil Novo and Uruará, which together comprise the Transamazônica Hub, which, by the way, is the most important cocoa region in the state. Pará still houses two more cocoa-producing regions, the Middle Amazon Hub and the Bragantina Hub.

Cocoa from the Amazon

The region is crossed by the Transamazônica Highway, the so-called BR-230, built by the military during the dictatorship, which was never completed (the initial project envisaged the construction of nine thousand km, but after more than four decades, only 20% were actually completed) and which many point to as the biggest cause of disorderly deforestation in the Amazon rainforest. Of the total of 1,751 km built, only under 10% are paved and several stretches, during the rainy season, are impassable, hampering the logistics of producers. The route from Medicilândia to Altamira is paved, a 90 km journey that, before being paved, could last four days in view of the quagmires. Yet, it is far from having the ideal conditions.

Panorama

The farm has 2027 hectares of area, with 200 thousand cocoa trees spread over 30 fields. In 2019, it produced 250 tons of almonds, 20% of which is special cocoa production. “It is still not possible to produce special cocoa on the entire property, but, every year, the planted area has been progressively increasing with a view to export,” explains Helton Gutzeit. It employs 30 CLT families, and the employees’ children attend agricultural school on the farm.

Aerial view of the Panorama Farm

They opted to plant a hybrid cocoa developed by CEPLAC (Executive Committee of the Cocoa Crop Plan), composed of the varieties Forasteiro Amazon, Trinitário and Criollo, whose characteristics are greater productivity and resistance to diseases.

The harvest

The first step in the selection process of the special cocoa is manual harvesting, where only ripe fruits are harvested, which have a golden color. Then, the cocoa is harvested by one of Panorama’s workers, who uses a flat wire basket carried on their back. Hence, the fruits are taken for fermentation, a key step to ensure the quality of the final product, chocolate.

After the selection, the fruits are broken with a short machete and placed in pieces of cloth and canvas of an appropriate size. After the break, bagging in fiber bags takes place. The almonds are separated from the skin of the fruit (for hygiene reasons and in order not to run the risk of contamination) and placed in plastic boxes. Then, they are transported to the fermentation house, where they are deposited directly in troughs.

The Amazon is the largest forest in the world, which is where cocoa is originated

“Fermentation lasts seven days, with the first stirring after 48 hours. After that period, the almonds are revolved every 24 hours. The troughs are covered with banana leaves to prevent the almonds from drying out on the surface and maintain the temperature. Then, the almonds are spread throughout the greenhouse area and dry with the aid of sunlight. Every 30 minutes they are rolled over. This process is completed with the almond break test,” explains Helton.

Cutting test

The quality of the fermentation and drying process is defined by means of the cutting test, where three basic factors are analyzed in each batch: if the almonds show up severe defects (molds, slates, in case they have been germinated), if the seed rate flattened is within the acceptable limit, which is less than 3%, and if there is a reduced amount of violet almonds.

“The process of producing our chocolate is done in a handmade way, where the whole almond is selected for roasting, which is the stage in which we define what the soul of chocolate will be like”, explains Helton.

As a result of so much work, in 2018 they began to invest in consultancy and fermentation tests, and in 2018 they participated in the 1st National Contest held by CIC (Center for Innovation in Cocoa), taking first and second places as the best almond in the Blend category . And, in 2020, they were in second place in the

same category.

International market

In November 2019, they participated, for the first time, in the Cocoa Awards, in Paris, an award that is part of the largest chocolate fair worldwide, and their almonds were selected among the 50 best in the world. It was a great opportunity to introduce their almonds to some of the most important French chefs, the famous brand Bonnat having recently purchased its first batch of almonds. “We are very proud and in contact with several other European chefs who have received samples and are very interested in producing Bean to Bar chocolates with Panorama almonds,” says Eunice.

Agroforestry and preservation of the Amazon

The diversity of fauna and flora at the Panorama farm

About 10 hectares of the Panorama farm were reserved for the production of agroforestry cocoa or cabruca (a term coined by the Bahians to designate a cocoa plantation in the shade of the Atlantic forest). It is a bet by the farm in the Bean to Bar chocolate market, whose chocolate-makers, in theory, are willing to pay a little more for cocoa beans, since agroforestry makes production more expensive. On the other hand, it is possible to achieve special aromatic notes, much appreciated by the international market. “Cocoa is very manual, very expensive, with labor difficulties. There is no perfect model, but we are trying to balance the environmentally friendly model with profitability. To that end, we are increasingly looking for sophisticated, international markets that cherish our effort to produce quality, organic cocoa in the middle of the Amazon rainforest, in a sustainable manner,” explains Helton.

The rest of the farm’s cocoa production is still aimed at the large industry.

Gutzeit chocolate

Unlike Helton and Elcy, who live on the farm, Eunice Gutzeit is in São Paulo most of the time and is responsible for exports and participation in international fairs. Attentive to the market, she is working to launch the final product, the Bean to Bar Gutzeit chocolates and for sales to the international market.

“I took some chocolate-maker courses but I do not consider myself an expert. We have an agreement with Casa Lasevicius, read the story here, to produce our chocolates, but I am also analyzing other possibilities, so that we can increase our production. We wish to stop producing just the raw material, in order to have our Gutzeit brand among the best in the world. I know it will take some time, which is required for the project to mature. I long to mix in our chocolates fruits of Amazonian origin such as cupuaçu, which we started to plant on the farm, and the first harvest will be harvested in January 2021, with the giant apricot from the Amazon, with the coumaru, with the açaí etc.,” Eunice states.

At that moment, Gutzeit chocolate is presented in three bars: 70% with cupuaçu, 70% only cocoa and 50% with milk. “Soon, we will have three more new versions, but we are still in the planning phase, as we have not defined which ones we will pick,” Eunice concludes.

Photos: Panorama Farm Credits